News

HYUNDAI WIA reveals nation’s first rear wheel drive based “2-speed 4WD system”

2025-04-03

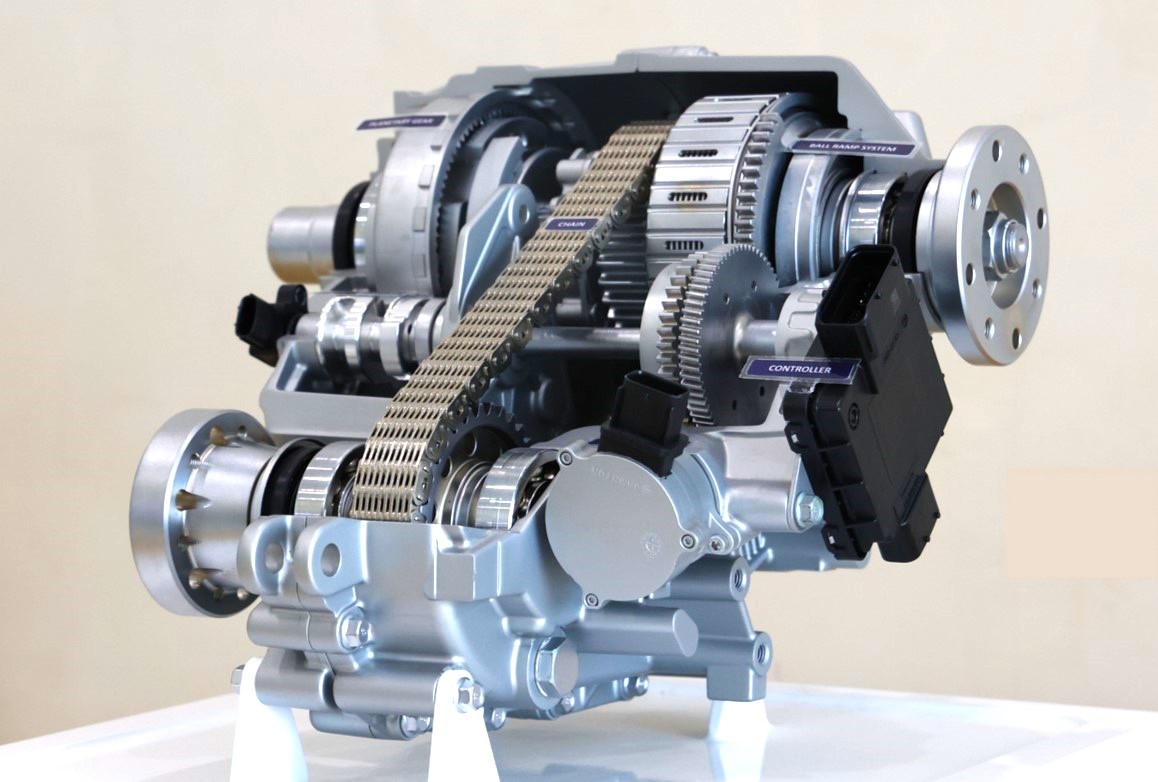

An open model of the nation’s first two-speed ATC developed by Hyundai Wia. The 2-speed ATC is a rear-wheel based vehicle component that distributes power between all wheels according to driving input for optimal driving performance.

Hyundai Wia has succeeded at local production of a four-wheel drive (4WD) component designed to distribute optimal driving force on all road surfaces.

On April 3, Hyundai Wia announced the development and mass production of its two-speed Active Transfer Case (ATC), a rear-wheel based electric 4WD component capable of controlling driving force according to driving conditions. The two-speed ATC component controls the distribution of driving force between the front and rear wheels depending on driving conditions, providing optimal driving performance for rear-wheel based vehicles. Hyundai Wia is the first company in Korea to successfully develop and mass produce the two-speed ATC. The component will be featured in the Tasman, Kia’s pickup truck.

Hyundai Wia researchers pose for a photograph in front of the two-speed ATC at the Hyundai Wia Uiwang R&D Center, on April 3rd. The 2-speed ATC is a rear-wheel based vehicle component that distributes power between all wheels according to driving input for optimal driving performance.

Hyundai Wia developed the two-speed ATC to ensure stable driving performance for any terrain. Drivers can select four driving modes (2 HIGH, 4 AUTO, 4 HIGH, 4LOW) depending on road conditions. For everyday driving such as highways or urban environments, drivers can select “2 HIGH” mode which is equivalent to rear-wheel drive. For everyday conditions requiring four-wheel drive, “4 AUTO” mode will actively control the distribution of drive force between the front and rear wheels when selected.

Hyundai Wia’s two-speed ATC also offers 4WD modes for tackling extreme terrain. On gravel or icy roads, the “4 HIGH” mode ensures stable power distribution to all four wheels. Additionally, the “4 LOW” mode delivers increased torque for extreme off-roading on sandy or rocky terrain or towing camping trailers by distributing over 2.7 multiples of driving force.

Hyundai Wia designed the two-speed ATC to perform a swift assessment and subsequent distribution of the required driving force according to driving conditions. Based on driver input and road surfaces an assessment is made every 0.01 second to calculate the required driving force. Additionally, the two-speed ATC controller unit has been incorporated into the main frame for improved maintenance convenience.

Hyundai Wia conducted extreme condition tests around the world to enhance stability of the two-speed ATC. Durability testing was conducted on the mountain roads of Korea as well as the deserts of California and UAE in scorching temperatures and sandy terrain. In addition, the icy roads of northern Sweden were utilized to rate performance reliability in -30°C conditions. Notably, a 30-degree snow covered slope in Sweden was traversed in “4 LOW” mode to test performance.

Hyundai Wia has now assembled a full lineup of 4WD components with the mass production of the two-speed ATC, and the company is gearing up to expand its global market presence. The plan is to target global automakers with a diverse range of products that includes the Power Transfer Unit (PTU) - a front-wheel based 4WD component with over 10 million units produced – and the Electronic Limited Slip Differential (e-LSD) which actively distributes driving force to the left and right wheels.

“The two-speed ATC was developed to ensure optimal driving performance in any road conditions. We will continue to push technological advancement to strengthen our position in the global automotive parts market.” said an official from HYUNDAI WIA.

Recent Posts

-

HYUNDAI WIA Awarded Gold Medal in Global ESG Assessment for Two Consecutive Years

-

HYUNDAI WIA Introducing a Wide Range of Mobility Based Artillery Systems at IDEX 2025

-

HYUNDAI WIA Employees Save 1% of Their Salary and Donate 10 Vehicles to Welfare Organizations

-

HYUNDAI WIA hosts ‘2025 Partnership Day’ … “Strengthening Technological Competitiveness and Supplier Collaboration in HVAC Module, etc.”

Youtube

Youtube Instagram

Instagram Blog

Blog Linkedin

Linkedin Post

Post Facebook

Facebook